Design of San Francisco International Airport’s (SFO) new airport traffic control tower not only was focused on functional goals – including meeting the strictest seismic event standards, offering maximum sightlines and accommodating state-of-the-art electronics – it also needed to serve as an iconic airport symbol.

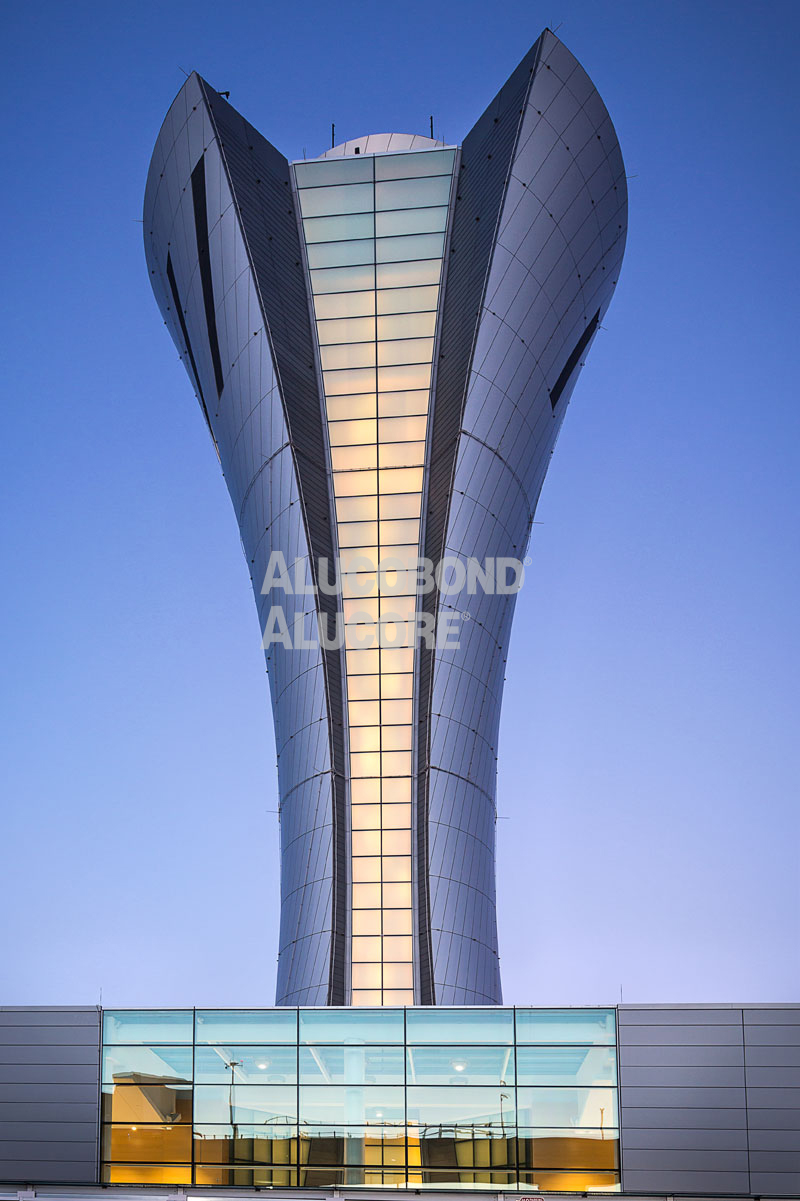

The resulting 221-foot-tall 5,652-square-foot shimmering-metal tower features a geometrically complex design resembling a sweeping torch that is topped with an offset control cab – the latter providing Federal Aviation Administration (FAA) air traffic controllers with an unobstructed 270-degree view of airport runways and taxiways.

The new tower – which is designed to withstand a magnitude 8.0 earthquake and remain operational – will replace the current airport control tower built in 1981 that does not meet stricter seismic standards. The new air traffic control tower is the tallest vertical self-centering post tension concrete structure in the United States and is designed to achieve LEED Gold certification from the U.S. Green Building Council.

A total of 10,000 square feet of formable 4mm Alucobond® Plus aluminum composite material (ACM) in the custom SFO Silver color clads this spiraling torch-shaped structure. (Recyclable Alucobond – which is manufactured with both post-manufacturing and post-consumer content – contributes LEED credits to building projects.)

The west face of the airport control tower is “opened” vertically with a backlit glass façade that stretches 147 feet in the air to create a local visual landmark. Situated above a new three-story FAA office building and walkways connecting Terminals 1 and 2, the open-core design allows passengers to gaze directly up into the tower through corridor skylights to view the cascading waterfall lighting.

“The tower lighting can be changed based on the mood of the airport,” according to Mark Costanzo, P.E., project manager, SFO, who said the façade’s changing LED colored lighting transforms the tower in recognition of holidays and special events.

In developing the tower’s design – which began in 2010 – SFO and HNTB personnel reviewed Olympic torch designs through the years as well as tower precedents from around the world. The resulting design reflects the SFO brand as an iconic symbol that is both “elegant and timeless in approach,” according to Paul Kim, AIA, NCARB, project manager, HNTB.

“This idea is manifested in the sweeping torch form and is the impetus for opening of the tower shell to expose the ‘core’ with a backlit glass façade, which greets passengers arriving along the upper-level roadway and SFO’s AirTrain,” said Kim. “The intent was to provide a tectonic and elegantly detailed façade with a subtle but dynamic skin with spiraling aluminum panel joints around the conical surface. We also saw an opportunity with the tower’s location. Unlike towers at most airports, the SFO tower is located immediately adjacent to drivers and pedestrians. We wanted people to experience the tower up close as well as from afar.”

The torch design is reminiscent of the historic pier torches utilized in the 1800s to guide ships to port in San Francisco Bay, according to Curtis Fentress, FAIA, RIBA, president, CEO and principal-in-charge of design, Fentress Architects.

“The tower was designed as an iconic symbol for the airport,” said Fentress. “It needed to be a long-standing building that was dramatic in form to serve as an airport logo but also symbolic of stability for passenger flights.”

While the tower’s cladding originally was specified with 3/16-inch aluminum plate panels, Keith Panel Systems Co. Ltd., of North Vancouver, British Columbia, Canada, suggested Alucobond aluminum composite material.

“We felt that Alucobond would be better suited to handle the specific challenges presented by the tower’s geometry,” said Paul Dalzell, operations manager, Keith Panels Systems (KPS). “We knew that Alucobond had much more flexibility and could be formed into these complex shapes.”

“Alucobond® was a material that could carry the shape of the building with an outward appearance that is sleek and dynamic,” said Fentress. “It gives a futuristic quality to the building. Technically, it was able to create all of the joints and worked well with the complex structural engineering designed to ensure that this building will be there after a seismic event.”

KPS spent approximately 1.5 years in pre-construction planning and four months fabricating approximately 1,500 Alucobond panels, which were installed by Pacific Erectors, Inc., of Rocklin, Calif., with the KPS System A Pressure-Equalized Rainscreen System.

To create this series of complex panel shapes, KPS utilized Autodesk Revit Building Information Modeling (BIM) software and the architectural 3-D printed models; the company also created a series of nine panel assembly and fabrication prototypes and two full-scale mockups.

“When we started modeling and prototyping, we discovered the tower geometry was dictated by a set of very specific mathematic rules,” said Dalzell. “This allowed us to confirm every dimension on each panel pulled from the model mathematically to ensure the panels would fit on site. This was an exhaustive process requiring manual input and calculation of hundreds of points along the perimeter of each panel. While this process validated the theoretical model and was used in prototyping, it wasn’t practical for full-scale production. We searched everywhere for software that would provide an automated flattening solution but found nothing. In the end, KPS employed a developer to build custom software for us.”