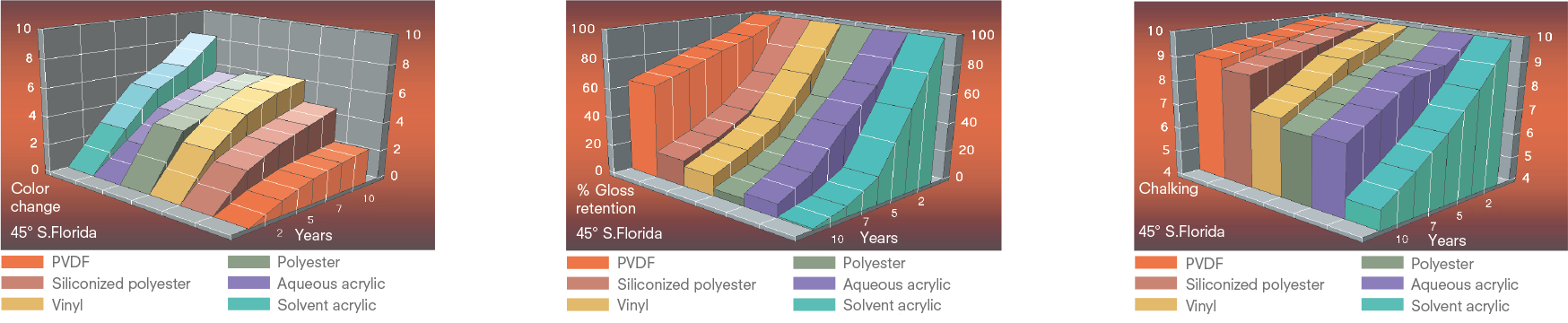

The superiority of Ultra – cote UV resistant lacquer systems (PVDF)is shown in the three graphs.

The values indicated are taken from tests conducted by the American Coil Coating Association (NCCA) on lacquered surfaces which were exposed to the extreme climatic conditions of South Florida for several years.

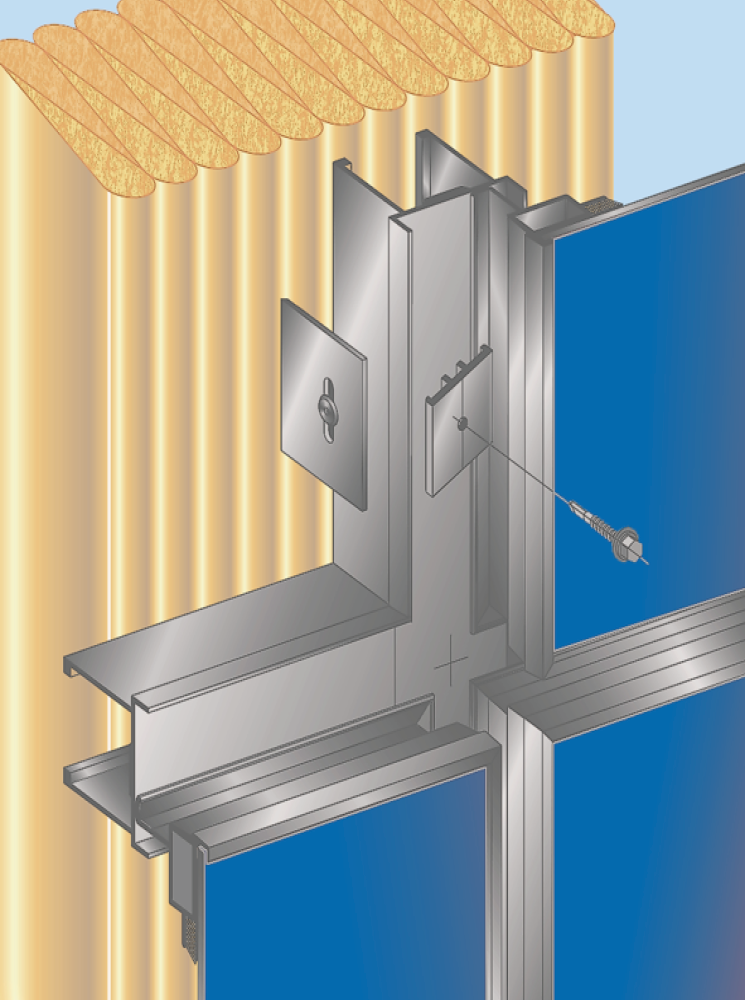

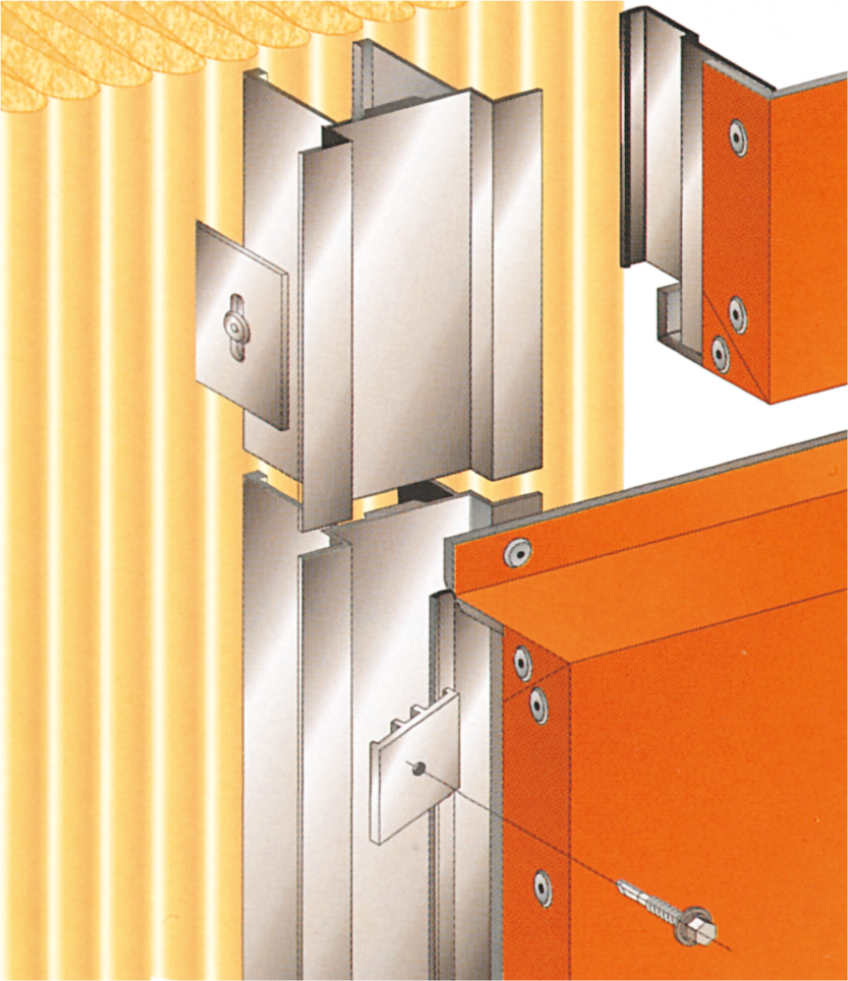

3AC Frame 90 System

(Patent NO.: ZL 2006 3 0166451.9)

3AC Hook-on System

(Patent NO.: ZL 2006 3 0166446.8)

3AC Cover Strip Joint System

(Patent NO.: ZL 2006 3 0166448.7)

3AC SZ-20 System

(Patent No.: ZL 2006 3 0166450.4)